Production Scale

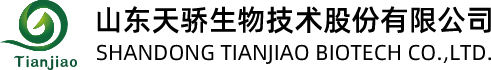

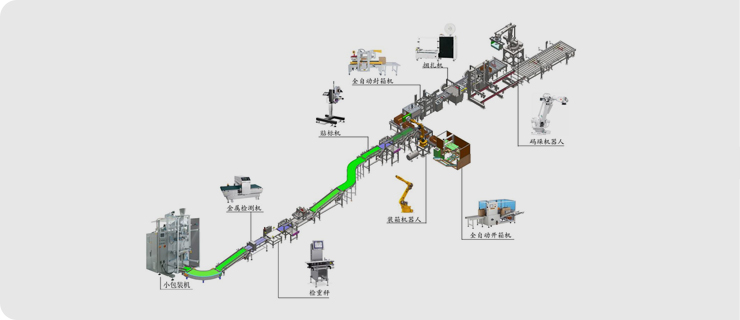

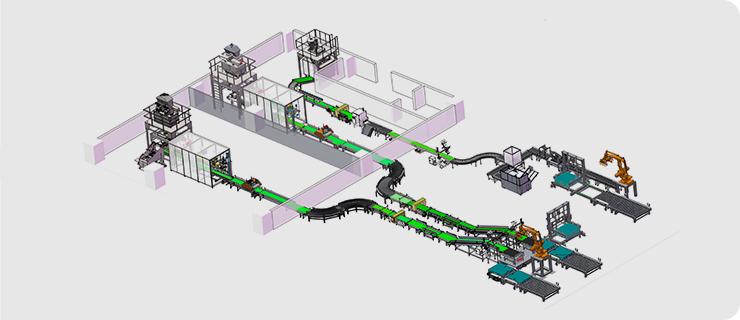

Production Process Flow

Production Equipment

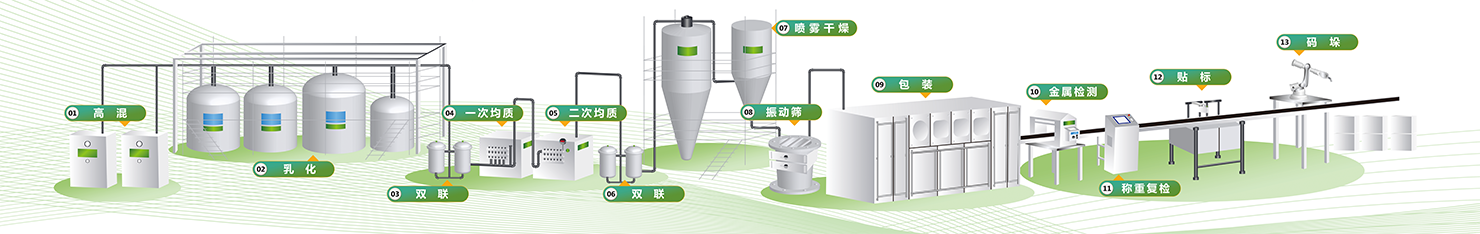

- Central Control System

-

Central Control System: All equipment and systems of the automatic production line are uniformly controlled and managed by the central control system.Adopting advanced automatic control technologies such as PLC (Programmable Logic Controller) and PC (Host Computer System), the central control system can realize automatic control, parameter monitoring, fault alarm, and other functions of the production line.

- Top-exhaust drying tower

-

The top-exhaust drying tower features advanced configurations of both fixed fluidized bed and three-stage fluidized bed. It takes the lead in adopting combined air intake of the air intake system and primary, intermediate, and high-efficiency three-stage filtration in China, ensuring clean air intake without polluting products and meeting the new milk powder regulations.

- Automatic Packaging Line

-

The clean packaging workshop is fully designed with stainless steel in accordance with national pharmaceutical and food GMP standards, adopting a straight-line bag automatic packaging and conveying production line;the entire line is equipped with an efficient electronic control management system, high-precision weighing and feeding device, and enhanced air extraction and exhaust system to ensure product quality;palletizing is performed by internationally advanced ABB palletizing robots to ensure high-speed production capacity.

- Functional Fat Powder Production Line

-

1.The production line is designed in strict accordance with infant formula milk powder standards and GMP standards.2. Adopts clean nitrogen automatic filling technology to prevent oxidation reactions of materials during preparation, which affects product quality.3. Removes and breaks bubbles, exhaust steam, etc., from the feed liquid to improve emulsification and encapsulation efficiency.4. Adopts world-advanced upward exhaust pressure spray to maintain uniform particle size of powder, reduce product adhesion, and effectively control product quality.

Food Safety Testing

Scientific testing, making every gram reassuring.

At Tianjiao Biotech, we believe quality comes from science.